Projects

Antipinsky

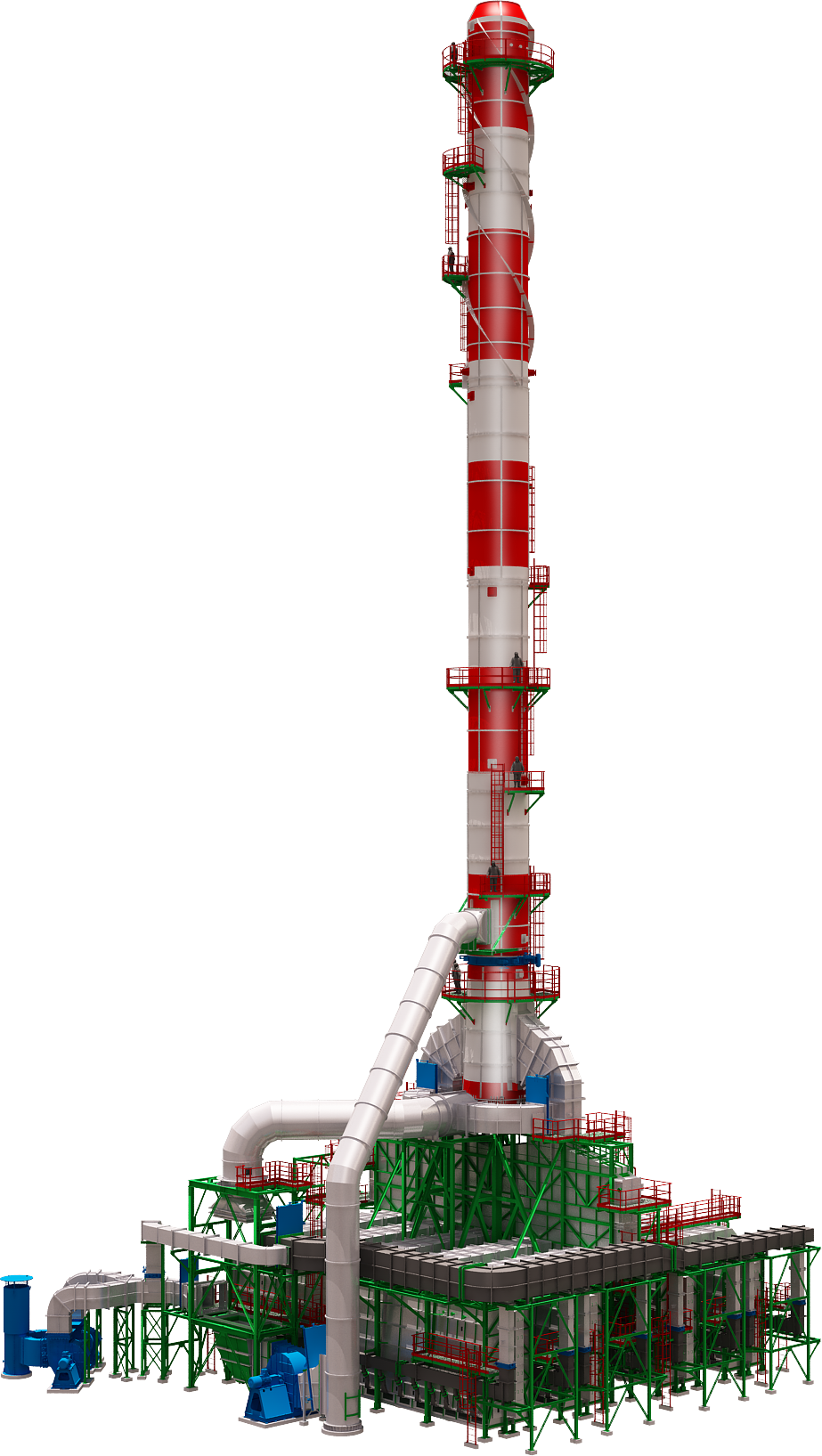

Cocker Heater for refinery

Antipinsky Refinery is unique due to the fact that it is first in Russia (in 35 years) private but not a state-run, independent of Vertical Integrated Oil Companies, commercial, constructed from the scratch oil refinery connected to the oil trunk pipeline (total capacity equals to 7.5 MTPA) and product trunk pipeline (total capacity equals to 2.3 MTPA) which capacity equals 7.5 MTPA, the quality of diesel complies with Euro-5 standard and in 2016 the processing depth has grown up to 98%. In 2018 the quality of gasolines complied with Euro-5 standard.

The Delayed Coker Heater has a base of about 34m x 34m and a height of about 7 meters, occupies an area of about 1200 square meters, and includes a steel stack having diameter 3.5m and height 64m, for a total weight of almost 600 tons.

34m x 34m for ∼ 1200 sqm

Diameter of 3,5m x 64m elevation

The design has been made with containerizable panels in order to optimize transport and subsequent assembly on site. The complete model consists of over 37,000 parts and 16,000 groups of bolts, for a total of more than 6600 assemblies. More than 100 assembly drawings for the site, 700 drawings of assemblies and sub assemblies, and 4000 drawings of prefabrication, as well as DXF files for nesting have been supplied.

The initial organization of the model in well-defined phases was important in order to be able to provide, during the development of modeling, the assembly and the detailed drawings to the production according to steps agreed with the same production, to optimize the time of construction.

The use of Tekla software Bimsight as a tool to exchange the information related to the 3D model was crucial for the optimization of the basic design (simplifying the design of the joints), to validate the entire project (interference checking between Tekla model Structures and equipment, such as fans, valves and dampers, supplied by third parties in 3D file format compatible), and to simplify the understanding of assembly drawings by the production.

Tekla BIM-AWARDS

C.F. & P. IVA: 02270640697 - Share Capital €12.500,00 fully paid up - CHIETI Company Reg. n° 02270640697 - REA: CH-165523